- Product Performance:

- Standard: GB 5237-2008, JISH, AAMA, GB, BS, En

- Alloy: 6005 T5/T6, 6060 T5/T6, 6061 T4/T6, 6063 T5/T6, 6463 T5/T6, 6082 T5/T6, etc.

- Surface Treatment: Mill finish, Powder Coating, Anodizing, Wooden grain, Electrophoresis, PVDF Painting, Sanding blasting, Polishing, etc.

- Further Process: Drilling, Bending, Welding, Precise cutting, Punching, Fabrication of finished products, etc.

- Certificate: CE, DNV, TUV, ISO9001

- Send More Specification by Email : epc@huadongonestop.com

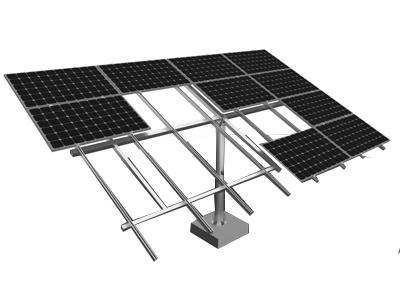

DC Solar Solution Program & Photovoltaic Frame Module & Stent

HUADONG Group provide one-stop photovoltaic project solutions, including products such as cables, transformers, photovoltaic modules, and energy storage cabinets. We provide one-stop technical solutions based on customer needs, provide comprehensive project process tracking, and ensure timely project completion.

HUADONG GROUP Can Provide the products related to Solar DC Cable Project.

Aluminium Profile For Solar Panel

Aluminium profile solar panel frame and mounting bracket are normally used to seal and fix solar battery components. it can be used to create integrated frames (including frames, brackets and connectors) for solar panels in various situations.Compared with other metal options, aluminum extrusion are lighter than other metals, so Aluminum solar panel frame is easier to transport and assemble in remote areas where large solar power plants are common. Aluminum is corrosion resistant, which adds to the weather resistance advantages of these solar panel architectures.

Fiberglass reinforced polyurethane composites

PU Pultruded Solar Module Frames represent a cutting-edge advancement in photovoltaic (PV) module support structures. Utilizing polyurethane (PU) composites through the pultrusion process, these frames offer a superior alternative to traditional aluminum frames. They provide enhanced mechanical strength, exceptional corrosion resistance, and improved thermal compatibility with solar glass, making them ideal for diverse environmental conditions. Their lightweight nature and insulating properties further contribute to the efficiency and longevity of solar installations.

Photovoltaic panels, composite material frames

- Product Performance:

- Excellent insulation performance

- Corrosion and salt spray resistance

- Customizable color options

- Low carbon emissions

- High yield strength

- Prevents backsheet cracking

- Prevents component bending

- Reduced costs and increased efficiency

- Send More Specifications by Email: epc@huadongonestop.com

Photovoltaic modules and composite material bracket characteristics

- Product Performance:

- Low density, 23% to 27% of steel.

- High strength: Ultimate tensile strength of 722 MPa.

- Excellent corrosion resistance.

- Strong designability: Meets diverse requirements for strength, rigidity, corrosion resistance, UV resistance, and color.

- Lightweight, corrosion resistance, insulation & PID resistance

- Price: Compared to aluminum alloy structures, it’s 20,000-25,000 RMB/MW lower.

- Structural Advantage: Composite materials utilize T-nuts, eliminating the need for pre-installed sliders in the slots, improving installation efficiency.

- Custom Specifications

- Length x Width (mm), Wall Thickness (mm), Density (g/mm³), Weight per Meter (g/m³)

- Send More Specification by Email : epc@huadongonestop.com

Key Features

- High axial tensile strength, surpassing that of typical aluminum alloys

- Excellent resistance to salt mist and chemical corrosion

- Non-conductive material, reducing the risk of Potential-Induced Degradation (PID)

- Lightweight design for ease of transportation and installation

- Thermal expansion coefficient closely matching that of solar glass

- Enhanced weatherability with long-term UV resistance

- Environmentally friendly with lower carbon footprint

Applications

- Residential rooftop solar systems

- Commercial and industrial solar installations

- Utility-scale solar farms

- Offshore and coastal solar projects

- Building-integrated photovoltaics (BIPV)

Technical Specifications

- Material Composition: Polyurethane composite via pultrusion process

- Tensile Strength: Exceeds that of standard aluminum frames

- Corrosion Resistance: Certified under IEC 61701 (salt mist) and IEC 62716 (ammonia) tests

- Thermal Expansion Coefficient: Approx. 60–100 × 10⁻⁶/°C, closely matching solar glass

- Electrical Resistivity: Volume resistivity up to 1×10¹⁴ Ω·cm

- Certifications: TÜV Rheinland and TÜV SÜD certified

Material characteristics and manufacturing process

- Features: Polyurethane composite materials offer lightweight, high strength, excellent weather resistance, acid and alkali resistance, and salt spray resistance, making them widely applicable.

- Manufacturing Process: Main materials: continuous fiber, modified polyurethane, and functional coating.

- Process: Pultrusion – Polishing – Painting – Quality Inspection – Packaging and Warehousing

Performance comparison of traditional materials and composite materials

| physical property | |||

|---|---|---|---|

| Fiberglass reinforced polyurethane composites vs aluminum alloy | |||

| properties | unit | aluminum alloy | Polyurethane composite materials |

| model | – | 6060-T5 | 40*27 glass fiber full yarn |

| density | g/cm3 | 2.7 | 2.1 |

| bending strength | Mpa | 170-230 | 700-1500 |

| tensile strength | Mpa | 200-300 | 600-1300 |

| flexural modulus | Gpa | – | 40-50 |

| insulativity | – | Conductive body, prone to PID | Insulator, no potential difference, no risk of electric couple corrosion PID |

| Carbon emissions per unit | CO2/T | ≈15.8 | ≈0.23 |

| coefficient of expansion due to heat | W/m.k | 23 | 6*10-6~10*10-6 |

TECHNICAL & SALES SUPPORT

If you have any questions, please contact us. We’ll do our best to help.